The discussion on resin vs plastic miniatures continues and it will do so for some time to come. Deciding on whether to buy resin or plastic miniatures is often one of the first questions for any D&D newcomer. It’s clear that both materials have their advantages but ultimately it comes down to your own personal preferences.

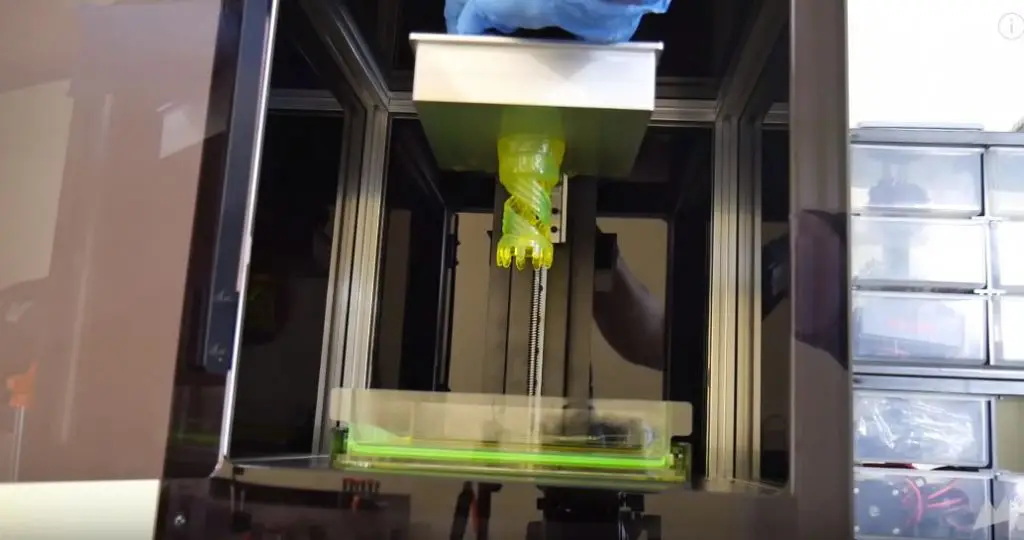

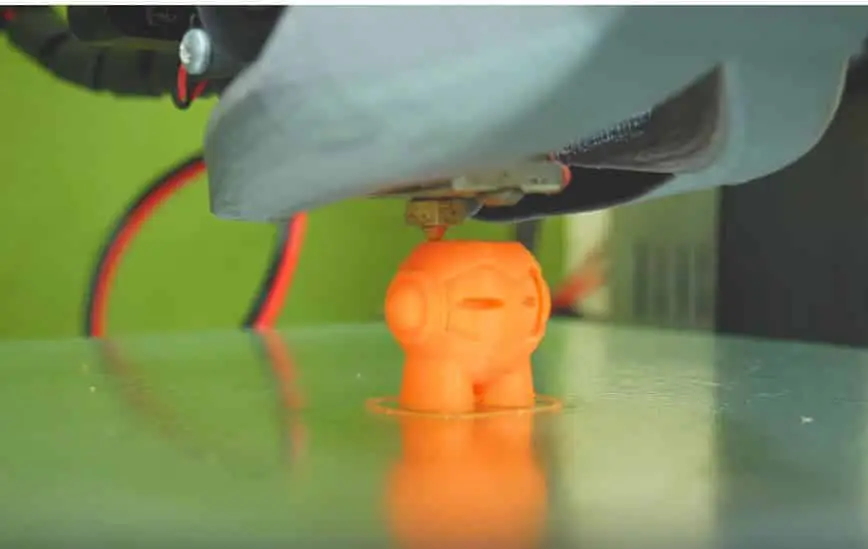

The arrival of 3D printers has given resin-based and PLA filament-based miniatures a serious boost. However, for this discussion, we are more concerned about the usability of the material than the actual manufacturing process. We are the ones who buy the miniatures to paint, customize, and hopefully enjoy for years to come.

So, it only makes sense that we opt for those miniatures that are made with the most usable material. It makes our lives a lot easier working with durable materials, especially when we’ve got several miniatures to fill for our campaigns and one-shots!

In this article, we will break down the two materials, resin and plastic, and see how they compare over several factors. We’ll be looking at manufacturing, preparation, painting, customization, and breakages.

Let’s take a closer look and find out which miniature material is going to be more beneficial to you, or maybe you’ll find out that building a collection which combines the two materials is going to be the most productive route.

Working with Resin Miniatures

To make this comparison fair, we’ll start at the top and explain why manufacturers would choose resin over plastic. Resin miniatures are popular among manufacturing companies who deal with small to medium-sized order runs and unique character designs. It’s cheaper than pewter which has been an industry standard material for years and this means that companies don’t need to outlay as much money for small orders.

It keeps their production costs down and that means a more competitive price for the customer. On the flip side of this is the fact that resin molds do not tend to last very long, hence why they are mainly used on small orders. Larger orders would mean working through several molds and this could lead to slight differences in detail from one mold to another – not great for quality control!

Lastly, resin is known to bubble from time to time during the creation process which can greatly affect the overall design. This is quite a big issue because these miscasts, as they are known, cannot be recycled.

So, you can see the benefits of using resin in certain situations for manufacturers but what about us, the paying customer? Well, the one main and underlying factor when using resin is that it can hold a lot of detail.

For the professional painters out there, this is absolutely huge and gives them the chance to create some truly stunning characters and designs. The fact that resin can offer so much detail per miniature does mean that painting becomes a lot more time-consuming.

The intricacy of the design with the detailed body, clothes, and accessories from a resin-based miniature requires maximum patience and a skilled hand if a good job is to be made of it.

Nothing is perfect though and before the painting can take place you’ll need to spend a significant amount of time on preparing your resin miniatures.

The process of using resin leaves a residue that stops paint from holding correctly, so it’s recommended to clean your resin miniatures in soapy water before you apply the primer. Also, if you need to make any adjustments that will create dust then you must wear protective masks. Resin is highly toxic when inhaled so do be extra careful.

Lastly, if you’re looking to use glue then you’ll need to opt for super glue over the standard plastic glue.

On the whole, resin miniatures do come with one or two benefits in certain situations. It’s a light material which is useful for some, but not so much for others, and the high level of detail will attract those of us who enjoy intricate painting projects.

However, if you like your miniatures to be durable and safe from heavy-handed friends then resin might not be the right option for you. All of that time spent painting your miniatures and your collection is not something that you want to risk with flimsy material. If you’ve got ideas for one-off characters and unique designs then we recommend giving resin a closer look. It will give you the depth and detail to make those ideas come to life upon the D&D table.

Resin Miniature Pros

- Resin is affordable

- Holds a high degree of detail

- Ideal for larger, unique designs

- Cheaper than metal/pewter

Resin Miniature Cons

- More fragile than plastic

- Resin is not recyclable

- A hard and time-consuming material to prepare and paint

- Hazardous material when customizing

Resin Miniature Tip

If you receive any warped resin miniatures or components then try leaving it in hot water (60-80 degrees) for around half a minute, depending on the size of the part in question. The heat of the water makes the material a lot easier to adjust which could save you unnecessary breakages when trying to bend or force the parts into their correct position. Remember, resin is not the strongest of materials and it will snap a lot easier than plastic.

Working with Plastic Miniatures

Plastic miniatures make up the bulk of most D&D collections. The material is durable and cost-effective when you’re looking to grow considerable-sized collections of miniatures. Manufacturing companies will produce plastic miniatures when they have at least several thousand on order due to the more expensive molding process. Unlike the resin molds, plastic molds last a lot longer so again this proves profitable for larger orders.

Plastic mini’s and mass-production go hand in hand. Over the last several years, plastic has proven to give us the best all-around quality when buying D&D miniature bulk sets.

Why? Plastic is strong enough to withstand the rough and tumble on the D&D table, it holds enough level of character detail for us to enjoy, and it usually comes with a reasonable price per miniature. Another great thing about plastic is that it can be recycled which is exactly what we want in this day and age.

Manufacturers get a great deal when combining plastic with mass-production miniatures but what about the paying customer? What benefits do we get from buying plastic miniatures over other materials? As mentioned, plastic is cheap and we can get a lot more for our money when buying in bulk.

Given that the plastic miniatures are cheapest, you can be more experimental when it comes to customization. Modifying a plastic mini makes a lot more sense as it’s not going to cost a great deal if things go wrong. Modifications sometimes sound great in principle but they don’t always result in the desired effect after you’ve cut away wings, arms, or accessories. The small price of a plastic mini is a lot easier to accept if things do go wrong!

The amount of detail can vary but overall you’ll find that plastic will not give you the level of detail that resin offers. However, preparing plastic for painting is going to be a little less time-consuming than if you’re using resin. You’ll most likely be able to jump straight to the priming stage with plastic and miss out the “washing off the residue with soap” stage that resin material requires.

Although, if time is on your side then a quick wash will not do any harm with plastic mini’s – a quality paint job is all in the preparation. Using plastic miniatures is a great choice for beginners as it makes the design learning curve a lot less costly than if you were to use metals or resin. It only makes sense to practice painting and modifying on cheap mini’s first.

Plastic Miniature Pros

- Cheap per-miniature cost

- Perfect for building large-scale armies

- Useful for modifications

- Stronger than resin

- Any waste can be recycled

Plastic Miniature Cons

- Molds can be expensive for small order runs

- Only offers a standard level of detail

- Doesn’t hold paint as well as other materials

Plastic Miniature Tip

Get your hands on a can or two of 3M Plastic Primer paint. This is excellent for priming plastic and its form is slightly elastic meaning that your paint is less likely to crack or chip if the piece bends a little. You’ll find 3M Plastic Primer paint in most home improvement stores.

Our Conclusion

At this point in time, until the process of manufacturing resin miniatures has been refined, we’d recommend keeping the bulk of your miniatures in plastic and then, if you so wish, build up your centerpiece heroes in resin. You can make the most of the extra detail that comes with using resin and create extravagant heroes complete with all the trimmings.

A good rule of thumb is to keep as much of your gameplay miniatures in plastic, especially the armies in which numbers can run up into the hundreds. Check out our guide on where to buy D&D Miniatures Bulk for more ideas on building up your miniature collection.

Overall, looking at the pros and cons of each material, we think that building your miniature collection with resin miniatures is completely fine and I believe leaving it up to the end consumer after we laid out the pros and cons is the route to go. However, it all comes to preference at the end of the day

. How much time and effort are you willing to put into the painting process of your miniatures? If you’re looking to build an exceptionally detailed and award-winning collection that is more likely to be admired than played with, a resin-based collection full of detail is your answer. If you’re looking to build up your collection with basic “table-ready” paint jobs then plastic is going to be a lot more profitable for you, in terms of both time and money.

Recommended Reading

Where To Buy D&D Miniatures Bulk

The best solution is to hunt down and buy D&D miniature bulk sets. Painted or unpainted, there are lots of deals to be found online.

Where to Find D&D Paper Miniatures Templates

There's a cheap and cheerful way of building up your collection. All you need to do is buy and download the D&D paper miniatures template and print them out